The Perfect Coating Solution for Academic and Commercial Research Labs

iCVD is emerging as a leading platform technology for micron and nanometer coatings, capable of depositing dozens of coating chemistries with a broad range of properties and functionalities.

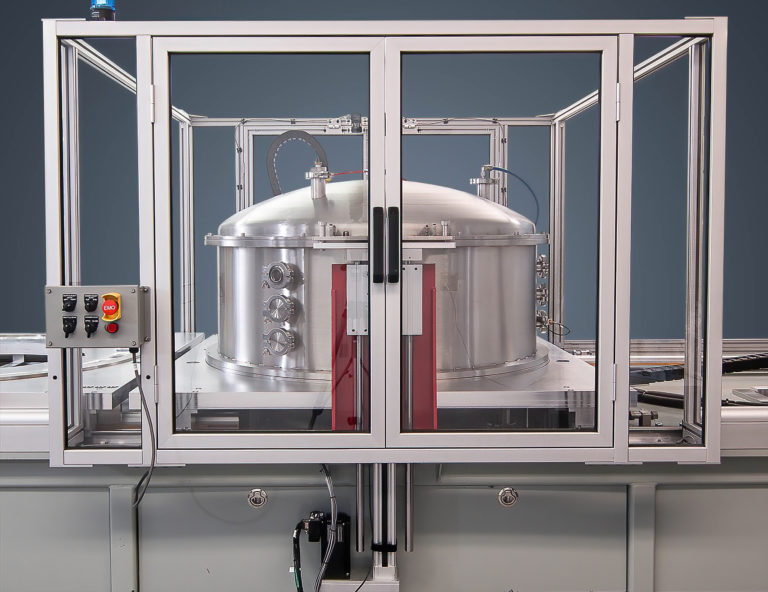

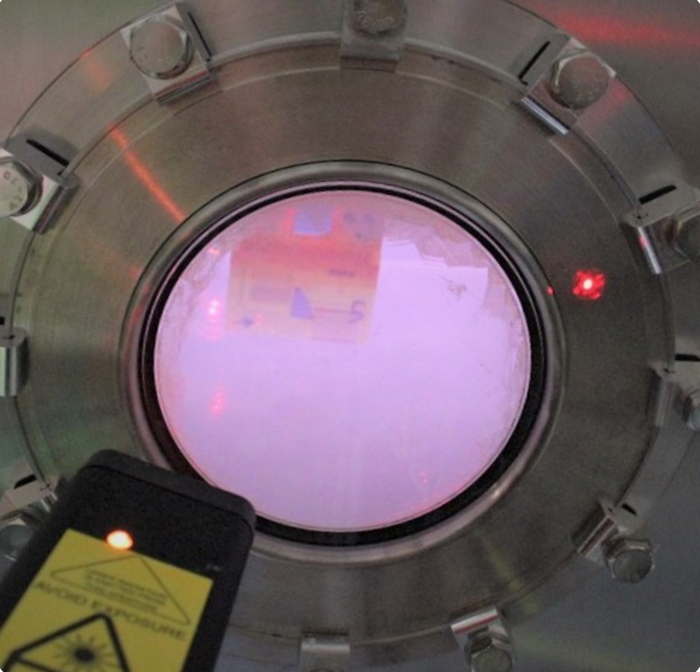

GVD’s iLab coating research system is a laboratory-scale chamber that is fully-automated, and ideal for exploring initiated chemical vapor deposition in any academic or commercial research lab. Our scientists and engineers work with you to deliver a research or educational tool that grants the greatest range of possibilities for coating development utilizing a recipe-driven, easy-to-use, automated system. We help you reduce design and installation time, material discovery and optimization period, and help advance to technology licensing for custom applications.

- Small footprint, fully contained in a vented enclosure

- High performance system with customizable configurations

- Low cost of ownership & maintenance

- Ability to deposit a variety of materials, including polymers, inorganics and many others

- Intuitive PC-based control system

- Options for full-service expert support

Core System Features

| Features |

| Dimensions: 6.5’ Width, 6’ Height, 3’ Depth |

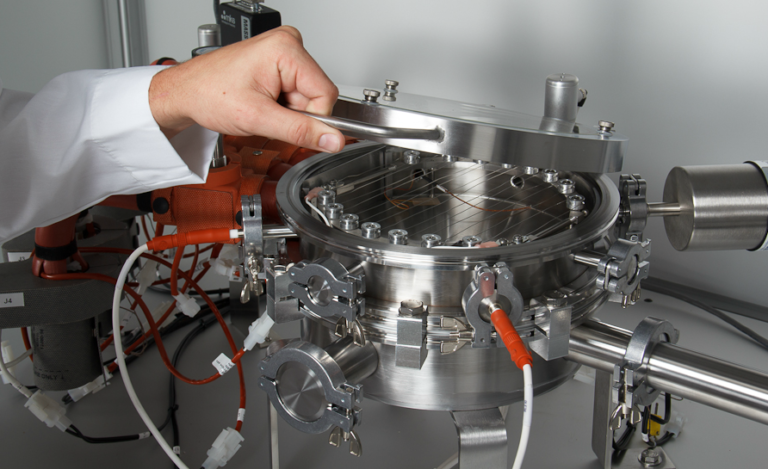

| Custom stainless steel vacuum chamber with temperature controlled stage |

| Tensioned hot filament array |

| Heated precursor delivery system with automatic temperature control |

| Real time thickness measurement via optical interferometer |

| Automatic pressure control via heated capacitance manometer and throttling valve |

| Oil-sealed rotary vane vacuum pump with foreline trap and outlet mist filter |

Optional Features

| Equipment Add-Ons |

| Additional precursor feed lines |

| Low-volatility precursor delivery system |

| Programmable DC Power Supply for filament heating |

| Safety and Automation Package |

| In-situ thickness measurement via quartz crystal microbalance (QCM) |

| Dry pumping system |

| Automatic flow control |

| Recipe-driven control system |

| Help & Support on Demand |

| Extended service and support agreements |

| On-site Training |

| Licensing for custom applications |

GVD’s Head Start Plan

GVD offers a ‘head start’ plan that includes ‘recipes’ and R&D support as a starting point for vapor deposition specialists and those entirely unfamiliar with the technology. GVD’s team of expert scientists and process engineers will help develop coating chemistry solutions to help you get experimenting right away.

GVD Coating Equipment is Found in:

Undergraduate unit operations labs

Academic research labs

Government labs

Biomedical

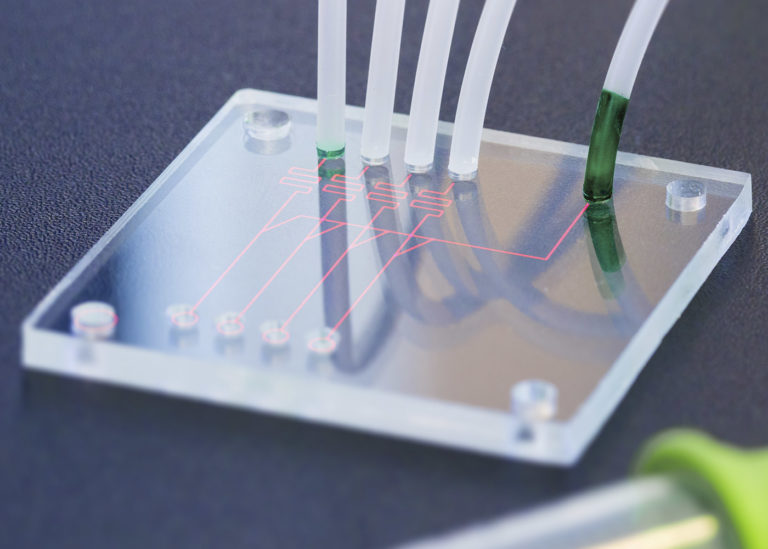

Microfluidics

Nanotechnology

Coating Equipment FAQs

Standard lead time is 16-20 weeks, but demo or used equipment may be available with a shorter lead time.

Yes! Many of our iLab customers have no prior experience with iCVD. We often offer process support and/or codevelopment agreements

It is difficult to coat substrates with oCVD and iCVD coatings using the same process chamber, but we have sold standalone oCVD coating systems, and can offer a single iLab system with two process chambers: one for iCVD, and one for oCVD

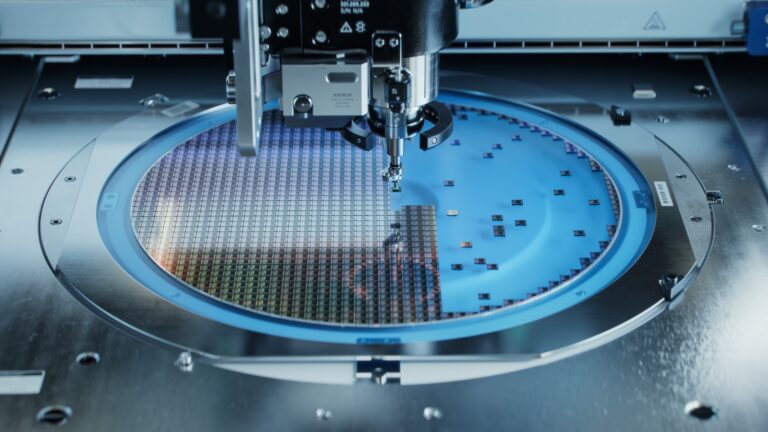

A standard iLab system can coat substrates ranging from a 6” wafer, up to 1 cm in height

Substrates must be vacuum compatible, meaning they will not outgas, shrink, or expand when exposed to a vacuum environment.

iLab systems can be tailored in a number of ways to suit a customer’s intended application. The most common customizations include number and type of precursor inlets, vacuum pump type (oil vs. dry), thickness measurement scheme, and spare chamber ports.

Yes!

I’d like to discuss coating equipment with a GVD engineer