In recent years, organometal halide perovskites have become the most promising class of next generation solar materials due to their extremely high efficiencies (>20%), their amenability to cheap manufacturing and the potential for >40% efficiency when paired with other solar technologies.4–6. With their relative ease of...

Read More

Enhance, Protect, and Prolong with GVD Coatings and Systems

GVD’s Ultrathin Polymer Coatings are based on the Chemical Vapor Deposition technology and proprietary materials that outperform conventional coating approaches. Whether you need help streamlining a manufacturing process, upgrading your product capabilities, or have a new cutting edge application, GVD’s premier coating services are fast and scalable and can be tailored to virtually any application.

Transform Surfaces Using CVD

Industries Served

Consumer Products

Medical Devices

Defense and Aerospace

Industrial Applications

Application Spotlight

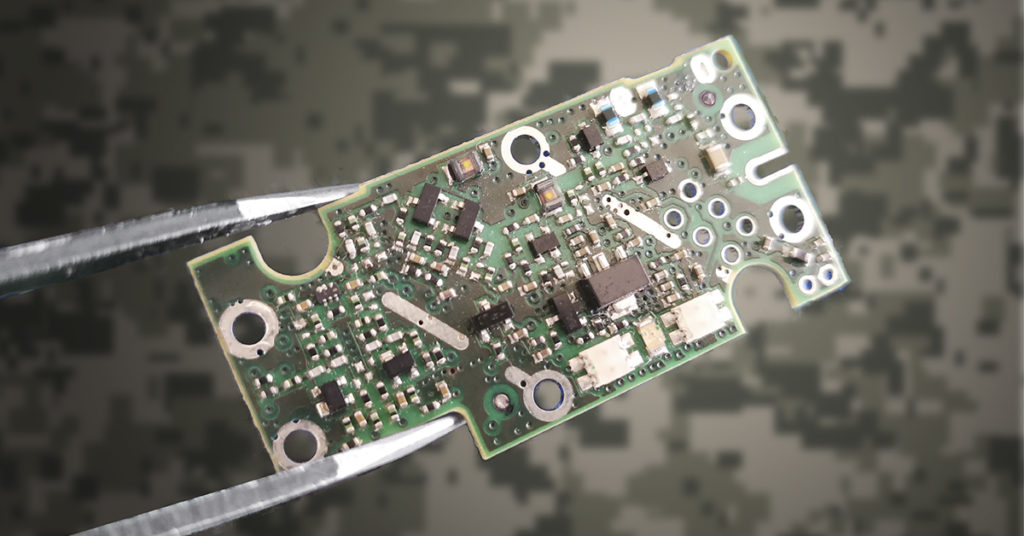

Facilitating Advanced Packaging and Heterogeneous Integration

Advancements in electronics design and manufacture, as well as the general trend toward optimization on all fronts – size, weight, power, and cost (also known as SWAP-C) have put a lot of pressure on electronics designers in recent years. These include a push for miniaturization and...

Read MoreEliminating Product Denaturing In Parenteral Syringes

Parenteral drug administration using prefilled single-dose syringes has the potential to add ease and safety for treating a variety of diseases, including autoimmune, arthritis, diabetes, and others. Using pre-filled syringes presents the ability to reduce medical errors and enable patient-controlled self-therapy. However, the traditional method of...

Read MoreApplication Spotlight

Protecting Perovskite Solar Cells from Water Vapor-Induced Degradation

In recent years, organometal halide perovskites have become the most promising class of next generation solar materials due to their extremely high efficiencies (>20%), their amenability to cheap manufacturing and the potential for >40% efficiency when paired with other solar technologies.4–6. With their relative ease...

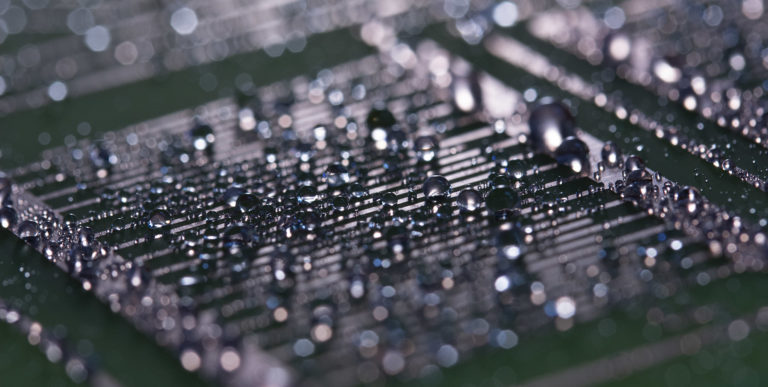

Facilitating Advanced Packaging and Heterogeneous Integration

Advancements in electronics design and manufacture, as well as the general trend toward optimization on all fronts – size, weight, power, and cost (also known as SWAP-C) have put a lot of pressure on electronics designers in recent years. These include a push for miniaturization...

Eliminating Product Denaturing In Parenteral Syringes

Parenteral drug administration using prefilled single-dose syringes has the potential to add ease and safety for treating a variety of diseases, including autoimmune, arthritis, diabetes, and others. Using pre-filled syringes presents the ability to reduce medical errors and enable patient-controlled self-therapy. However, the traditional method...

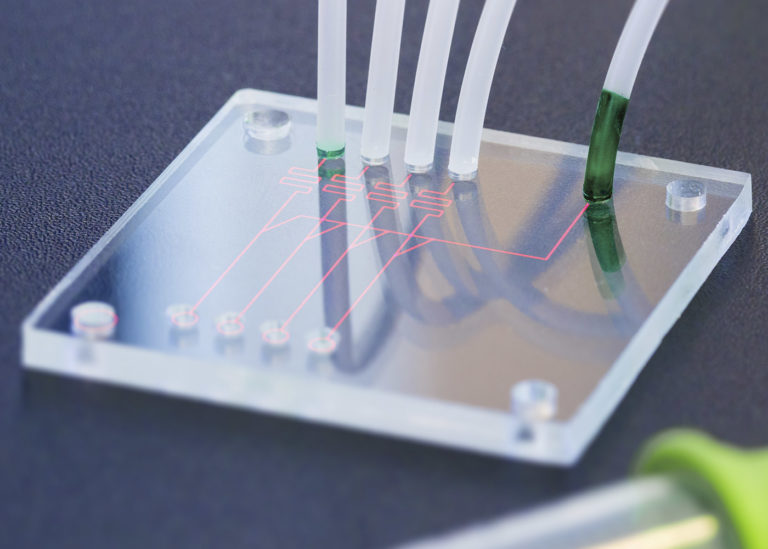

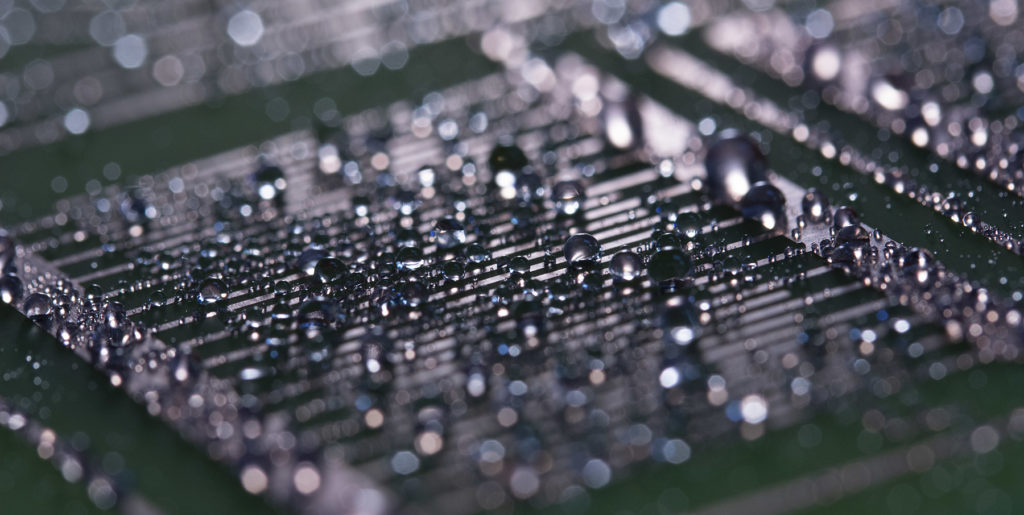

Maximizing Droplet Motion for Microfluidics Applications

Electrowetting has emerged as one of the most commonly used techniques for manipulating the movement of small liquid droplets on surfaces, utilized in lab-on-a-chip devices, optics, and displays. It is achieved via electromechanical reduction of a liquid’s contact angle with an applied electric field on...

For High Frequency Electronics

SignalSeal is an advanced and proven vapor deposited polymer coating that provides unprecedented protection for circuit boards & devices in extreme environments without adding weight or sacrificing RF or high-speed digital performance.

For Challenging Mold Structures

RapidRelease is an ultra-thin, permanent PTFE coating designed to provide clean release for the most demanding mold applications. RapidRelease provides quick and efficient demolding for higher quality parts, increased yields, and significantly lower operating expense.

For Solvent-free, Non-stick Surfaces

GVD’s thin film PTFE can transform surfaces to be non-stick, low friction, hydrophobic and lubricous through a contactless coating application free of harsh chemicals or high temperature processing.

Additional Coatings From GVD

Bar against the ingress of gases and liquids to protect even the most corrodible or oxidizable materials.

Provide electrically switchable wetting properties for electrofluidic devices with maximum voltage response for unprecedented droplet motion control.

GVD’s polymer coating experts are able to develop unique coating technologies to solve most surface coating challenges.

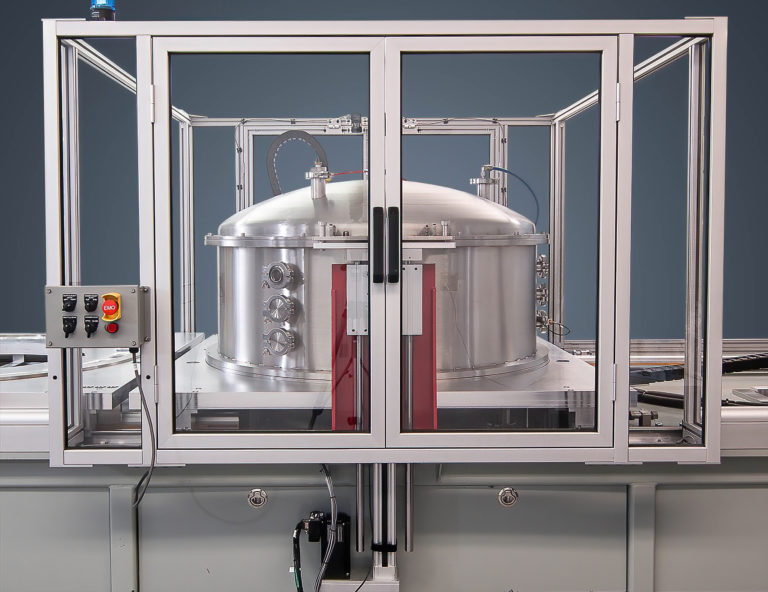

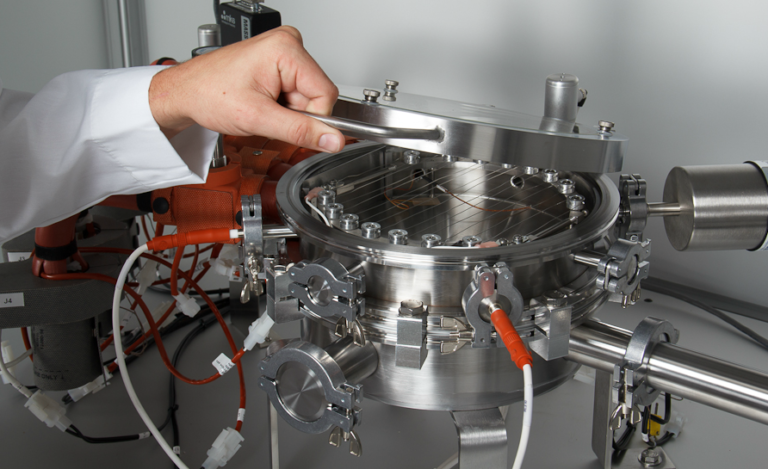

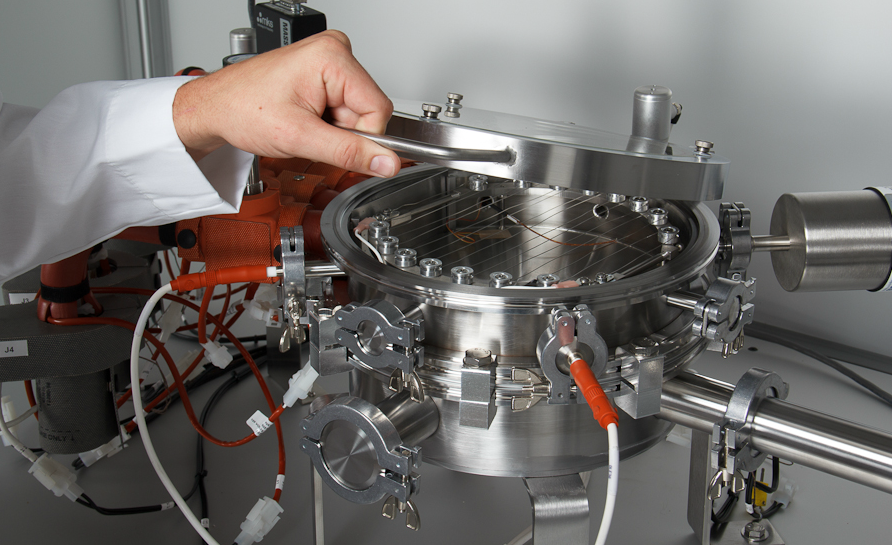

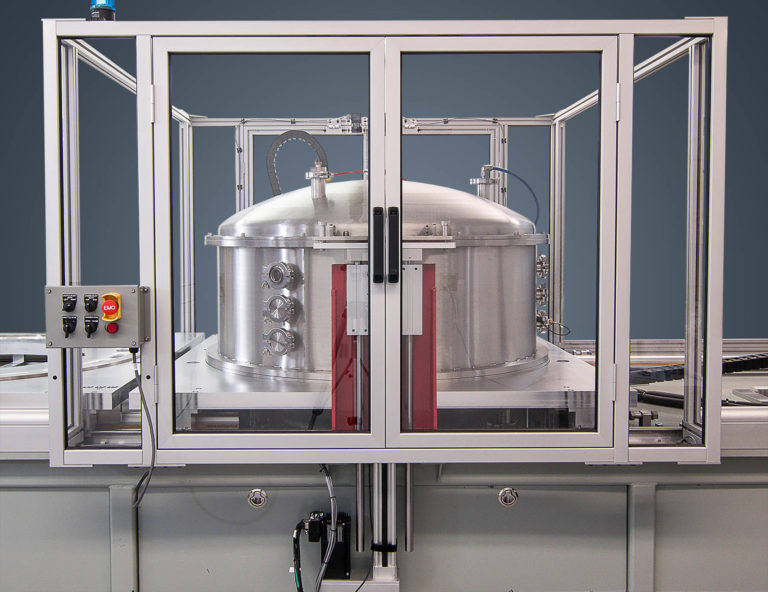

Coating Equipment

GVD’s coating equipment enables research and development laboratories to bypass the costly and time consuming process of developing a custom polymer chemical vapor deposition (CVD) system to get to experimenting right away.

What’s New at GVD

Kayaku Advanced Materials Acquires SignalSeal from GVD Corporation

- Event

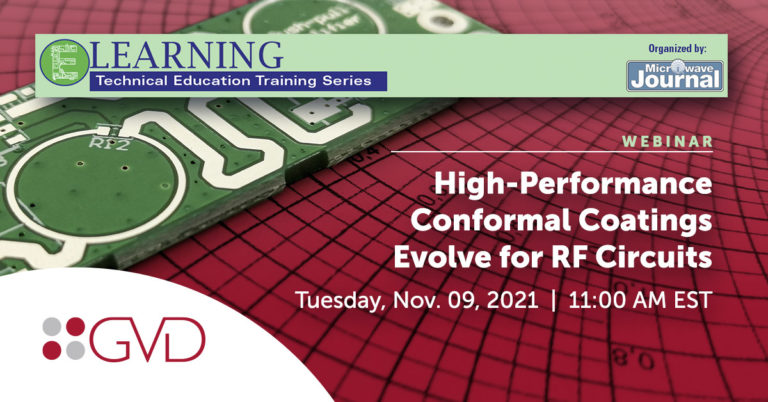

Webinar: High-Performance Conformal Coatings Evolve for RF Circuits

Yes!

I’d like to discuss my application with a GVD engineer.